Vial with septum for quality control testing

-

Assessment of microbial ingress - BD

Jun 8, 2018 · drug-vial spike adapters allow for reconstitution and multiple withdrawals of a drug from a single entry through a vial septum, they can leave residual drug volume in vials and may not adequately address hazardous drug exposure risk.2-4 Although such manipulations are typically carried out in a primary engineering control (e.g., biologic safety

Get Price -

Sealing it with Septa

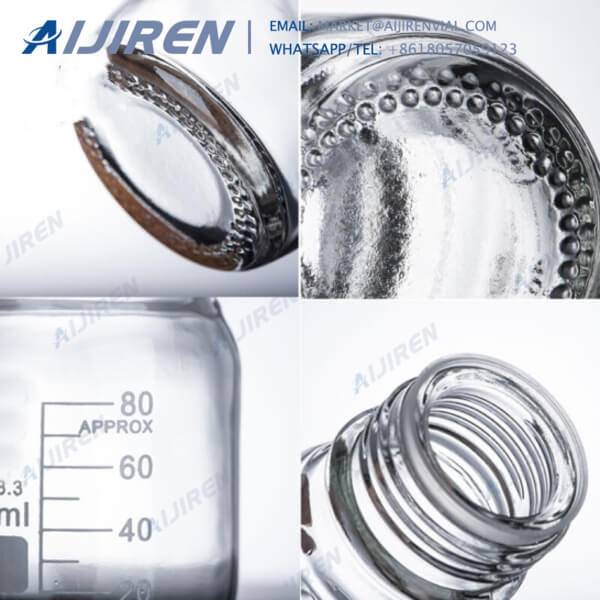

Jul 1, 2016 · Sample-vial septa must withstand multiple punctures during repeated syringe rinsing prior to injection, but there is no long-term requirement for a lasting seal. There are two remaining measures of vial septum performance: leakage and sample contamination. Vial septa can be made of softer and better sealing materials than inlet septa.

Get Price -

Sterility Testing | Pharmaceutical Microbiology | Sartorius

In this study, the closed system sterility testing device, Sterisart ® ️ septum version, was evaluated for the recurrent sterile extraction of samples. The results demonstrate that even after more than 100 repeated septum sampling events, which far exceeds any foreseeable sampling requirements, the septum remains intact and the growth media

Get Price -

The Pharmaceutical Capping Process-Correlation between

The vial sealing process is a critical process step during fill-and-finish operations, as it defines the seal quality of the final product. An adequate force to remove the f The majority of parenteral drug products are manufactured in a glass vials with an elastomeric rubber stopper and a crimp cap.

Get Price -

Troubleshooting a Leak or Poor Chromatography on the Aijiren

Nov 10, 2022 · Install a new septum into the blue leak test vial. Place the blue leak test vial into priority position 1 (111 vial model) or into tray position 1 (12 vial model). Set the carrier pressure to a low flow If using HS Control or GC Control: a Cool the GC inlet and column oven. When cool, press [Carrier].

Get Price -

Aliquoting for longer QC stability - Randox Laboratories

Feb 22, 2017 · Aliquoting reconstituted material is an ideal way of extending the control’s open vial stability. This will ensure that your laboratory minimises the amount of QC material wasted and saves money by eliminating the need to purchase additional controls.

Get Price -

1 Annex 1 Manufacture of Sterile Medicinal Products - PDA

51 follow carefully established and validated methods of manufacture and control. A 52 contamination control strategy should be implemented across the facility in order to assess 53 the effectiveness of all the control and monitoring measures employed. This assessment 54 should lead to corrective and preventative actions being taken as necessary.

Get Price -

Septum Selection Guide Vials and Closures - Fisher Sci

characteristics. The septum is provided with a thin 0.005” PTFE layer laminated to highly pure silicone, and slit through the center for easier needle penetration and to release the vacuum that forms when a large volume of sample is withdrawn from a vial. This septum provides chromatographic characteristics similar to that

Get Price -

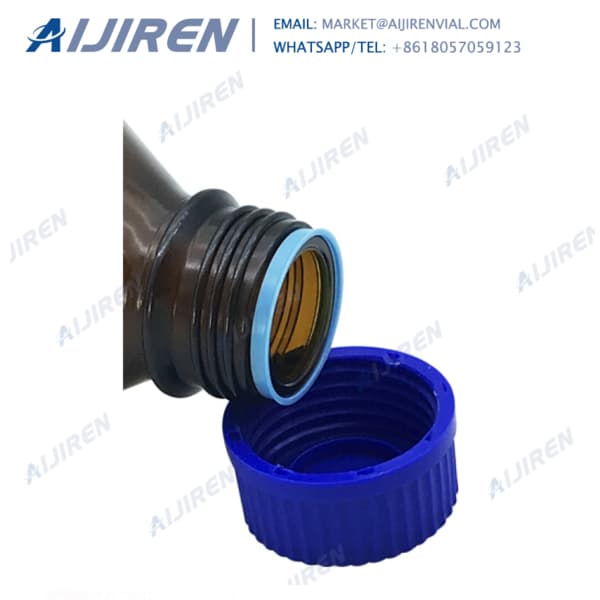

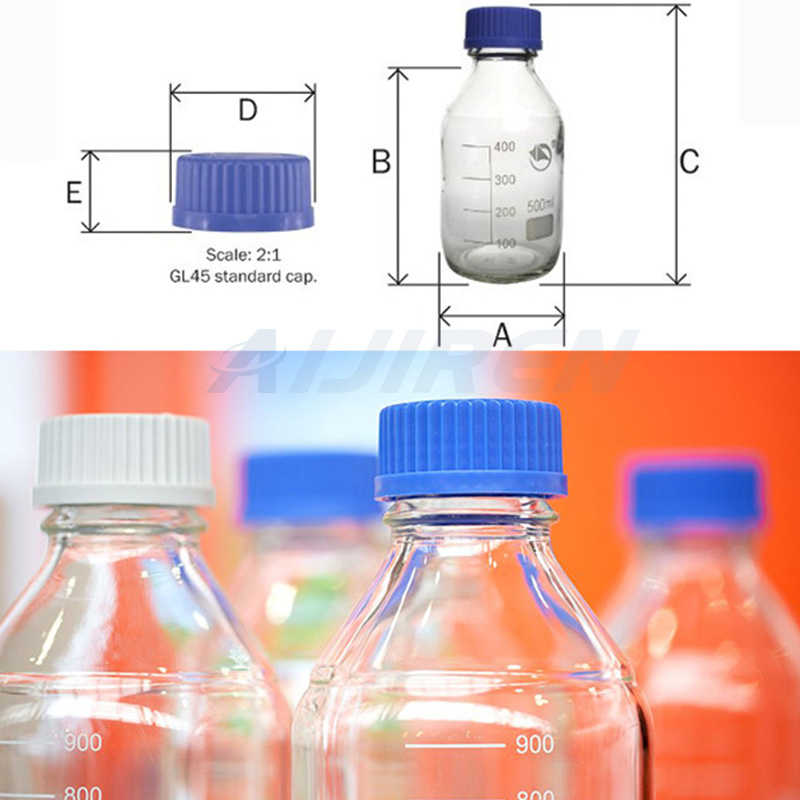

Aijiren Certified Vials, Caps and Septa - Postnova

Our 12 x 32 mm wide opening vials are most popular for economical and effective microsampling. Its polypropylene body has a glass flanged insert molded to the inside, so the sample comes in contact only with the 100 μL high quality glass insert and the septum. Use with crimp or snap caps.

Get Price -

ASHP Crosswalk of Guidances and Standards for Managing Single

American Society of Health-System Pharmacists | 7272 Wisconsin Avenue, Bethesda, Maryland 20854 | 301-657-3000| www.ashp.org Page 5 of 12 CMS TJC USP CDC FDA

Get Price -

Soybean-Casein Digest Broth with Resins in a Plastic Vial

Quality Control Certificates are provided with each carton of media. Quality Control Certificates list test organisms, including ATCC® cultures specified in the CLSI Standard M22, Quality Control for Commercially Prepared Microbiological Culture Media. The range of time-to-detection in hours was ≤ 72 hours for each of the organisms listed on

Get Price -

Sterile Drug Products - Apoteker Rudi

sterile products and the underlying importance of contamination control and compliance to current good manufacturing practice. • Quality and regulatory, including the application of good manufacturing practice regulations and guidelines, quality systems, good aseptic processing practices, and unique quality control testing of sterile dosage

Get Price -

1 2 BRIEFING 825 Radiopharmaceuticals—Preparation

224 difficult to access. One approach for disinfecting the vial septum in this type 225 of vial shield is to use a right-angle forceps to hold a sterile 70% IPA wipe 226 and direct it down onto the vial septum. It is also acknowledged that such 227 vial shields will disrupt first air contacting the vial septum during certain 228 handling

Get Price -

BACT/ALERT® Culture Media Bottles | Pioneering Diagnostics

BACT/ALERT ® Culture Media Bottles. INNOVATIVE & OPTIMIZED CULTURE MEDIA. The BACT/ALERT® Culture Media Bottles, used in conjunction with the BACT/ALERT® 3D or BACT/ALERT® VIRTUO®, offer advantages across every dimension of microbial testing.

Get Price