Septum Teflon: Resistance to Harsh Chemicals in Analytical Methods

-

Analytical Methods journal - The Royal Society of Chemistry

Journal scope. Analytical Methods welcomes early applications of new analytical and bioanalytical methods and technology demonstrating the potential for societal impact. We require that methods and technology reported in the journal are sufficiently innovative, robust, accurate, and compared to other available methods for the intended application.

Get Price -

Polytetrafluoroethylene (PTFE) | Definition, Structure, Uses

Polytetrafluoroethylene (PTFE), a strong, tough, waxy, nonflammable synthetic resin produced by the polymerization of tetrafluoroethylene. Known by such trademarks as Teflon, Fluon, Hostaflon, and Polyflon, PTFE is distinguished by its slippery surface, high melting point, and resistance to attack by most chemicals.

Get Price -

Bacillus spores: a review of their properties and - Springer

Oct 6, 2020 · Many factors determine the resistance properties of a Bacillus spore to heat, chemical and physical processing, including thick proteinaceous coats, peptidoglycan cortex and low water content, high levels of dipicolinic acid (DPA), and divalent cations in the spore core. Recently, attention has been focused on non-thermal inactivation methods based on high pressure, ultrasonic, high voltage

Get Price -

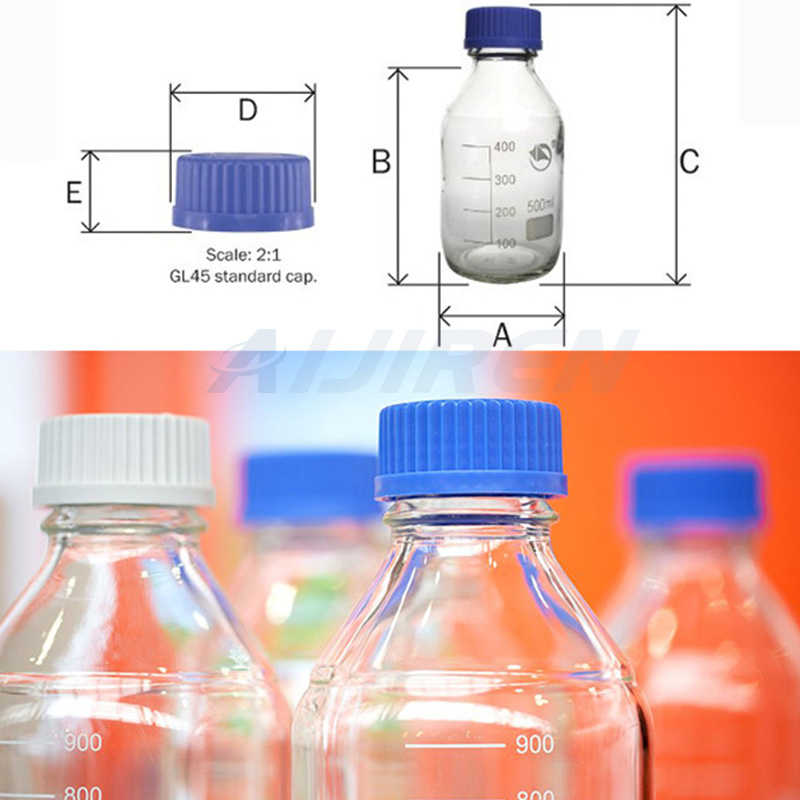

Stoppers | Fisher Scientific

Stoppers, also known as bungs, are used to give an airtight seal to laboratory flasks and test tubes by fitting tightly inside the neck of the container and preventing material from spilling. Stoppers can be made of glass, cork, rubber, or silicone. They are typically designed with a conical shape, but straight, flanged, and tapered options are

Get Price -

Septum at Thomas Scientific

Tuf-bond Septa (9711D10 to D45) Thickness: 100 mils Of silicone rubber with PTFE facing 10 mils thick Septa of butyl rubber, silicone rubber or rubber-laminated PTFE are available on special order. Septum diameter indicated in listings. Related Products: Screw Cap With Septum. Compare this item.

Get Price -

Cleaning Laboratory Glassware - MilliporeSigma

Rinse the glassware in a large bath of distilled water. Rinse with distilled water. To conserve distilled water, use a five gallon bottle as a reservoir. Store it on a shelf near your clean-up area. Attach a siphon to it and use it for replenishing the reservoir with used distilled water.

Get Price -

How to Use the Chemical Compatibility Chart Vials and Closures

Laminated septa will generally exhibit greater chemical resistance until the PTFE layer is punctured. Other factors that can affect chemical compatibility are temperature, pressure, whether there is direct contact between the material and the solvent and concentration of the solvent.

Get Price -

Method 603: Acrolein and Acrylonitrile - U.S. Environmental

trap account for the majority of contamination problems. The analytical system must be demonstrated to be free from contamination under the conditions of the analysis by running laboratory reagent blanks as described in Section 8.1.3. The use of non-Teflon plastic tubing, non-Teflon thread sealants, or flow controllers with rubber components

Get Price -

Septa Selection Tool | Thermo Fisher Scientific - US

Used primarily for routine analysis in gas chromatography. Offers moderate ability to reseal and good chemical inertness. Not recommended for multiple injections or holding samples for further analysis. PTFE is protective layer that once broken exposes rubber to chemical attack.

Get Price -

Septum Selection Guide Vials and Closures - Fisher Sci

The septum is provided with a thin 0.005” PTFE layer laminated to highly pure silicone, and slit through the center for easier needle penetration and to release the vacuum that forms when a large volume of sample is withdrawn from a vial.

Get Price -

Tips and Tricks for the Lab: Air-Sensitive Techniques (3)

Jul 2, 2013 · Repeat steps 4 and 5 for flask 2. Purge the syringe by inserting the needle through the septum of the solvent flask and into the headspace of the flask. Draw up the inert atmosphere into the syringe. Remove the needle from the flask and expel the gas from the syringe (Fig. 14, D). Repeat 3–4 times.

Get Price -

Cannula transfer - Wikipedia

Cannula transfer or cannulation is a set of air-free techniques used with a Schlenk line, in transferring liquid or solution samples between reaction vessels via cannulae, avoiding atmospheric contamination. While the syringes are not the same as cannulae, the techniques remain relevant. [1]

Get Price -

Polytetrafluoroethylene (PTFE) hollow fibers modified by

Jul 15, 2021 · This article presents a novel method of modifying polytetrafluoroethylene (PTFE) hollow fibers with a hydrophilic crosslinking network (HCN) to enhance their anti-fouling and chemical cleaning properties. The HCN-PTFE fibers show improved water permeability, salt rejection, and resistance to organic and inorganic fouling compared to the pristine PTFE fibers. The article also discusses the

Get Price -

Teflon/Polytetrafluoroethylene - an overview | ScienceDirect

Fluorocarbons. These have outstanding chemical, thermal and electrical properties. The four main types are described below. Polytetrafluoroethylenes ( PTFE) ‘Teflon’ or ‘Fluon’, these are the best known types of PTFEs. PTFEs resist all known chemicals, weather and heat, have extremely low coefficients of friction, and are ‘non-stick’.

Get Price -

Polytetrafluoroethylene - Wikipedia

Polytetrafluoroethylene ( PTFE) is a synthetic fluoropolymer of tetrafluoroethylene and is a PFAS that has numerous applications. The commonly known brand name of PTFE-based composition is Teflon by Chemours, [3] a spin-off from DuPont, which originally discovered the compound in 1938. [3]

Get Price