Glass Vials – Shell Glass Vials Manufacturer from Thane

Glass Vials Leading Manufacturer of shell glass vials, 2 ml glass vials & caps, clear glass headspace vials, clear screw glass vials with w/patch, high recovery glass vials and insert with bottom-spring glass vial from Thane.

The Glass Bottle Manufacturing Process

Glass Bottle Manufacturing Process. Press and Blow Process- a plunger is inserted first, air then follows to form the gob into a parison. At one point this process was typically used for wide mouth containers, but with the addition of a Vacuum Assist Process, it can now be utilized for narrow mouth applications as well.

Flask, Vial – All industrial manufacturers – Videos

The crimpnec vial from Altmann Analytik is designed with an 11 DN diameter and a height of 32 mm. It is a crimp micro vial that is made from klarglas. It is also engineered with a volume capacity of 1.1

Metal Caps for Glass Jars & Bottles – The Cary Company

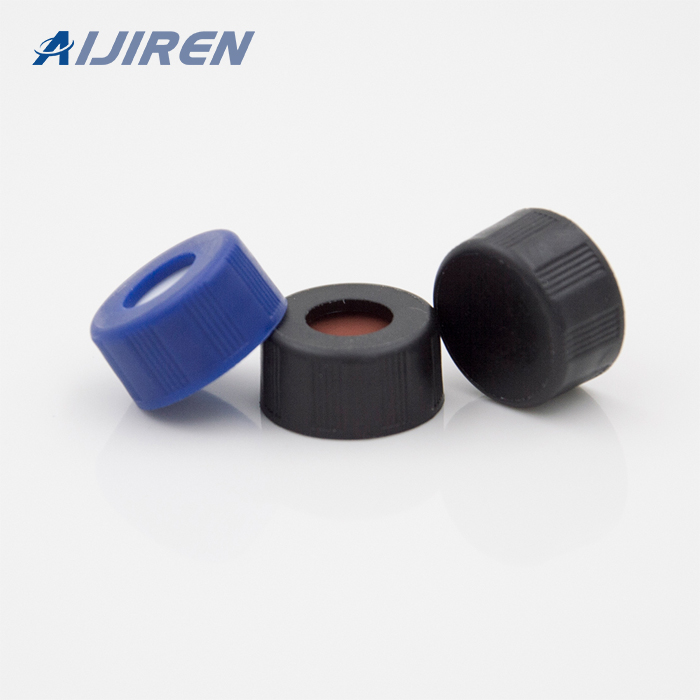

The Cary Company offers a wide variety of metal caps that are compatible for glass bottles, jars and jugs. These metal closures are FDA approved and available in Aluminum or Electrolytic tinplate (tin coated steel). Colors include Silver, Pewter, Aluminum, Gold, Black, White, Yellow, and Red. Various liners are available including Pulp & Poly, Pulp & Poly-Vinyl, F-217, Pulp & Aluminum Foil

Vial – vials Suppliers, Vial Manufacturers & Wholesalers

Mouth : Crimp Neck or Screw Neck, with or without Blow Back Ring; Tubular Glass Vials are manufactured using the highest quality glass tubing from all major manufacturers in the world. Treatments We also manufacture Internally Siliconized vials which are: Ideal for complete emptying of the vial Offer a reduced interaction between the glass s

Chromatography and Autosampler Vials from Cole-Parmer

Versatile Chromatography and autosampler vials designsed for superb performance. Choose from a variety of styles and sizes including 1- and 4- mL vials, and septa materials to match your equipment and applications.

Autosampler Vials & Caps for HPLC & GC | Thermo Fisher

Experiencing screw thread closure failures and/or sample evaporation? Use Thermo Scientific 2 mL SureStop Vials with AVCS Caps. Innovative screw cap & vial design; Ensures proper screw cap seal every time, independent of operator

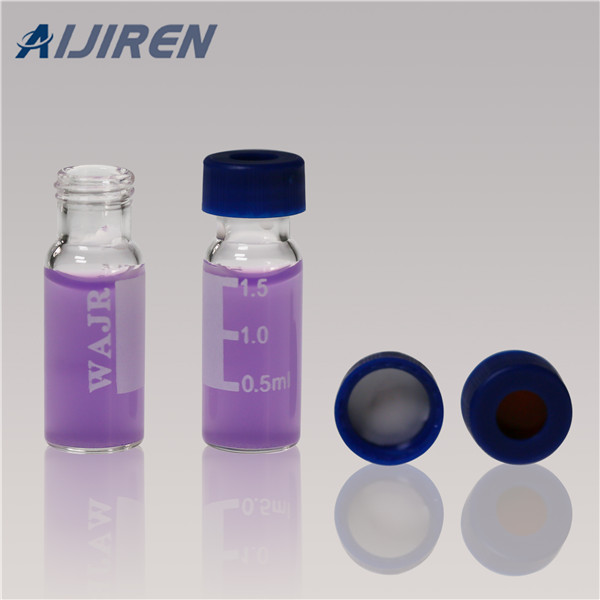

2mL Transparent Screw Chromatographic Bottle Autosampler

1)9mm screw vials can be used on all common autosampler. 2)Standard narrow neck design for GC and HPLC. 3)9mm wider opening for easy puncture. 4)Clear, type 1 class A borosilicate glass. 5)9mm PTFE/silicone septa, has excellent chemical inertness, acid and alkali resistance. 6)9mm screw black open top pp caps. 1.5mL Clear Screw Neck Vial, 9-425

Zhejiang Aijiren Technology Inc. – HPLC Vials, Headspace vials

Zhejiang Aijiren Technology Inc., Experts in Manufacturing and Exporting HPLC Vials, Headspace vials and 1090 more Products. A Verified CN Gold Supplier on Alibaba.com.

Missed Caps – Custom Packaging Machinery Manufacturer

Most automatic capping machines will use a chute to deliver caps to the bottles or other containers to be sealed. The chute presents a single lid to each individual container. For our purposes, a “missed” cap does not necessarily translate to a missing cap, but also to cross threaded, crooked or other erroneously placed closures.

Aerosol Can Caps, Manufacturer, Supplier-B.I. Packaging

Aerosol can cap is a plastic lid that fits over the aerosol can. Generally speaking, aerosol cans are made of aluminum or iron materials. After filled with gas/liquid, a certain pressure will be generated inside the aerosol can, normally there is an aerosol valve locked in the neck of the can body to maintain the pressure inside the can for a long time.

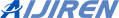

HPLC Vials 10-425 1.5ml Screw Vials

For example, 8-425 neck finish represents a vial with a diameter of 8 mm across the outside of the threads and a thread style of 425. Screw thread vials and caps are more expensive than crimp seals. Caps for screw thread vials are available with either an open hole for autosampler use and standard addition or with a solid top for sample storage.

Athena VIALS 1.5ML HPLC, Rs 400 /packet Athena Technology

1)9mm screw vials can be used on all common autosampler . 2)Standard narrow neck design for GC and HPLC. 3)9mm wider opening for easy puncture. 4)Clear, type 1 class A borosilicate glass. 5)9mm PTFE/silicone septa, has excellent chemical inertness, acid and alkali resistance. 6)9mm screw black open top pp cap. 1.5mL Clear Screw Neck Vial, 9-425

Cap and Neck Finishes. Commercial & Industrial Packaging

The experts at Pipeline Packaging are here to guide you through common neck finish and container cap options. Screw thread or continuous thread closure sizes are expressed with two numbers separated by a slash.

Plastic Bottles Manufacturing Process

Injection blow molding is performed in basically three stages. At the first stage, melted plastic is injected into a mold cavity to produce a preform parison. The preform is shaped like a test tube, but with a molded screw finish at the top. The preform is then transferred to the second, blow-molding stage.

-

Material: USP Type 1, Class A, 33 Borosilicate Glass

Application: Water analysis

Qty/Pack: 25pcs/pack or 100pcs/pack

Dimensions: 16 x 100mm

Neck Diameter: 16mm

Volume: 12ml

Payment: T/T

MOQ: 1 pack16mm Test Tubes for Water Analysis -

Dimensions: 27.5 x 57mm/27.5 x 75mm/27.5 x 95mm/27.5mm x 140mm

Material: USP Type 1, Class A, 33 Borosilicate Glass

Application: Environmental analysis

Neck Diameter: 24mm

Qty/Pack: 100pcs/pack

Volume: 20-60ml

Payment: T/T

MOQ: 1 pack20-60mL 24-400 Screw Neck Storage Vial ND24 -

Material: USP Type 1, Class A, 33 Borosilicate Glass

Dimensions: 16.6 x 60mm/18.5 x 65mm

Application: Environmental analysis

Neck Diameter: 15mm

Qty/Pack: 100pcs/pack

Volume: 8-12ml

Payment: T/T

MOQ: 1 pack8-12mL 15-425 Screw Neck Vial ND15 -

Material: Nylon; Hydrophilic PVDF; Hydrophilic PTFE; Hydrophobic PTFE; PES; MCE; Hydrophilic PP; Cellulose Acetate(CA)

Qty/Pack: 100pcs/pack

Application: Filter

Payment: T/T

MOQ: 1 packHPLC Syringe Filters