Addressing Sample Evaporation with Low-Permeability Butyl Rubber Vial Septa

-

All About Butyl Rubber - Properties, Applications, and Uses

2 days ago · Due to its low gas and vapor permeability, butyl rubber is an important material in the manufacturing of tubeless tires, inner tubes, sports-ball bladders, glove-box gloves, etc. As a waterproofing material, it is applied as a liner in tanks and ponds. It is used as a patching material for membrane roofs and as a sealant for insulated windows.

Get Price -

Aijiren Certified Vials, Caps and Septa - Postnova

Blue aluminum, clear PTFE/red rubber septa 100/pk Green aluminum, clear PTFE/red rubber septa 100/pk 5181-1216 Red aluminum, clear PTFE/red rubber septa 100/pk 5181-1217 Silver aluminum, PTFE/silicone/PTFE septa 100/pk Silver aluminum, PTFE/silicone septa 100/pk Silver aluminum, PTFE/butyl rubber septa 500/pk 5061-3370

Get Price -

Septa Selection Tool | Thermo Fisher Scientific - DE

A specially moulded seal with a PTFE insert. Sealing surface of Butyl and PTFE affects a more positive seal than non-PTFE-faced septa. Ideal choice for temperatures below 125°C. Good sealing characteristics, excellent resistance to most solvents with reduced coring and high puncture tolerance.

Get Price -

Septa selection guide

Black rubber septa Black Rubber septa are molded from a higher density rubber compound compared to the standard red rubber. This septum has characteristics similar to the gray butyl stopper. The Black rubber septum is an economical choice for applications where reduced levels of vapor penetration are desired. Temperature stability chart Min

Get Price -

Septa Selection Tool | Thermo Fisher Scientific - US

Butyl rubber/chlorobutyl rubber An economical choice for low temperature (< 125°C) or low-pressure applications. Not suitable for alkanes, benzene, chlorinated solvents or cyclohexane without a protective PTFE layer.

Get Price -

Septa | VWR

Septa. Septa are available in a variety of materials and thicknesses. PTFE Natural Rubber are moderately priced seals for GC and HPLC with good chemical properties. They are ideal for multiple injections due to high resealability, but not as easy to penetrate as PTFE/RR. PTFE/High Performance Rubber is a highly pure synthetic red rubber septum

Get Price -

Bromobutyl versus Chlorobutyl Rubber Formulations - General

Jun 25, 2019 · The question is often raised as to when to choose a bromobutyl- versus a chlorobutyl-based component. The answer is – it depends. They are comparable in terms of permeability for oxygen and water. Primary differences will be found in their extractables profiles, as different compounds are employed for curing, stabilization, etc.

Get Price -

Septa Selection Tool | Thermo Fisher Scientific - UK

The septum you choose for your autosampler vial can impact sample evaporation, sample security, needle bending and blockages, and instrument down time. Don’t let the complexities of septa selection slow you down. Use the simple online Thermo Scientific SureSTART Selection Guide to find the right septa and vial for your analysis.

Get Price -

920969-00 Factors to Consider While Selecting Stoppers for

They have low permeability to air and moisture. Nitrile rubbers are oil and heat resistant but leaching of components of the formulation is significant. Chloroprene rubbers are similar in properties to butyl rubber but are more expensive. Silicone rubber is heat resistant up to 2500 °C but the process of

Get Price -

TurboMatrix Headspace Samplers - PerkinElmer

20 mm Butyl, Pre-assembled Cap/Septa/Spring 100 N9306269 Clear 20 mL Headspace with Write-On Patch and Fill Lines Gray Butyl, Kit Unassembled Cap/Septa/Spring 100 N9306270 Gray Butyl, Kit Unassembled Cap/Septa/Spring 1000 N9306271 PTFE/Red Rubber Septa, Pre-assembled Cap/Septa/Spring 1000 N9302978

Get Price -

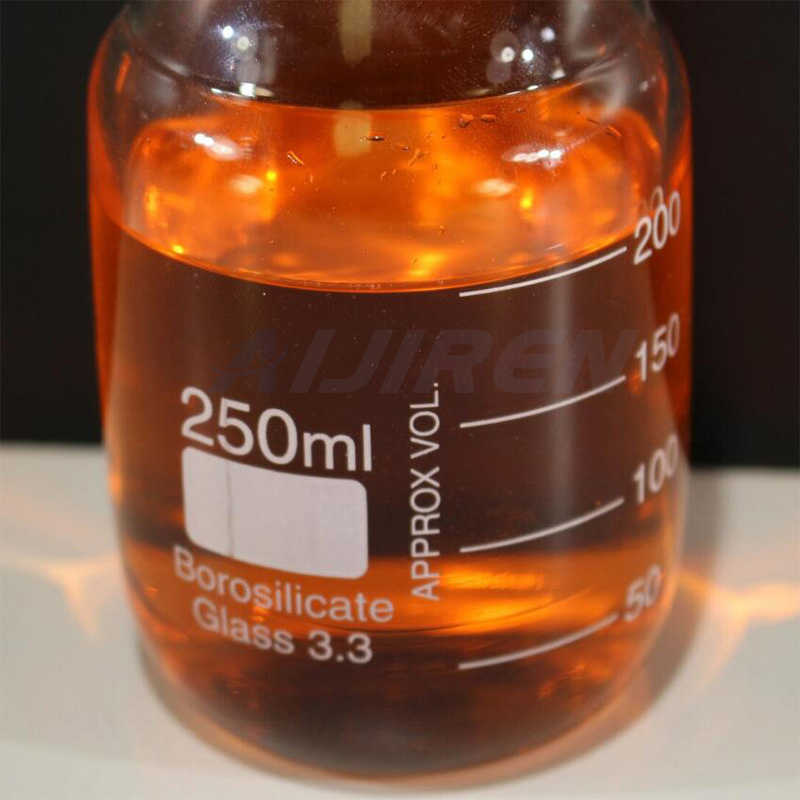

20mm Crimp Vials with Butyl Rubber Stopper--Aijiren Vials for

Excellent for long-term storage. Deactivation and MS Certification are also available. The butyl rubber product is an off-white rubber-like solid with a density of 0.92g/cm3. It is odorless, insoluble in water, and soluble in hexane and chloroform. The product also has low air permeability, good airtightness, and good resistance.

Get Price -

Accessory Product Data Sheet - .NET Framework

Butyl rubber/PTFE septa are used with ketones and acids, and where silicone-containing septa do not perform well. Both types of silicone and butyl rubber septa have a PTFE barrier layer which faces the sample, which reduces the contact between the sample and the silicone and butyl rubber.

Get Price -

Sealing it with Septa

Jul 1, 2016 · Sample-vial septa must withstand multiple punctures during repeated syringe rinsing prior to injection, but there is no long-term requirement for a lasting seal. There are two remaining measures of vial septum performance: leakage and sample contamination. Vial septa can be made of softer and better sealing materials than inlet septa. One of

Get Price -

Septa Selection for Autosampler Vials - Hplc Vials

Sep 9, 2022 · Butyl Rubber/chlorobutyl Rubber. An economical choice for low temperature (< 125°C) or low-pressure applications. Not suitable for alkanes, benzene, chlorinated solvents or cyclohexane without a protective PTFE layer. Silicone Rubber. Excellent septa choice for volatiles with very low background peaks and low permeability.

Get Price -

Septum Selection Guide Vials and Closures - Fisher Sci

The low durometer of red rubber allows for easy needle penetration even with thin bore GC needles. PTFE/Red Rubber septa are not recommended for multiple injections with long run times or retention of samples for further analysis after initial puncture. PTFE/Silicone Septa: (T/S)

Get Price